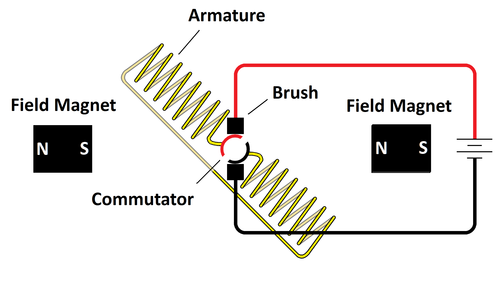

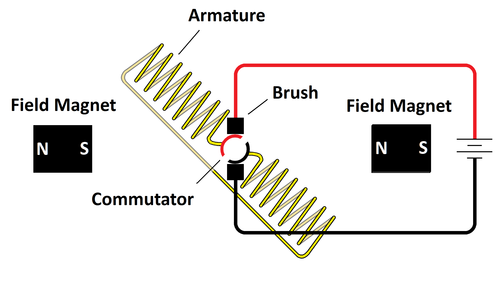

An electric motor uses the attraction

and repulsion of electromagnets and permanent magnets to produce rotary

motion. The following is a diagram of a permanent magnet DC motor. It

works by sending a current through a coil of wire, making that coil an

electromagnet. That coil will then be attracted or repelled by

permanent magnets. The coil is on an axle so that it will rotate. The

magnetic forces will cause it to rotate one way or the other, depending

on the polarity of the applied voltage.

|

A permanent magnet DC motor |

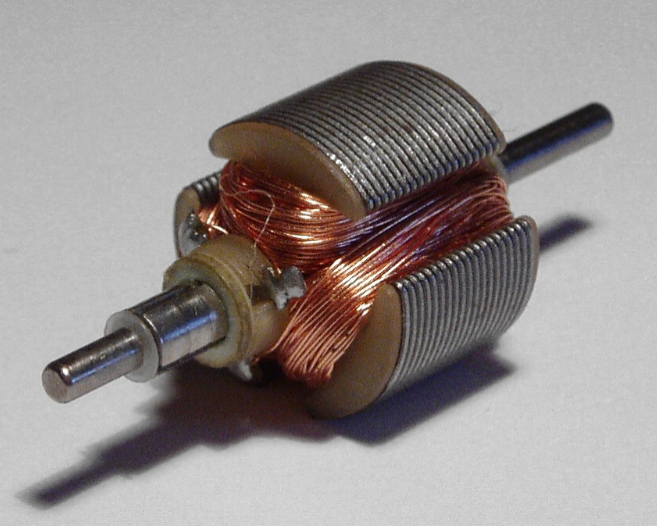

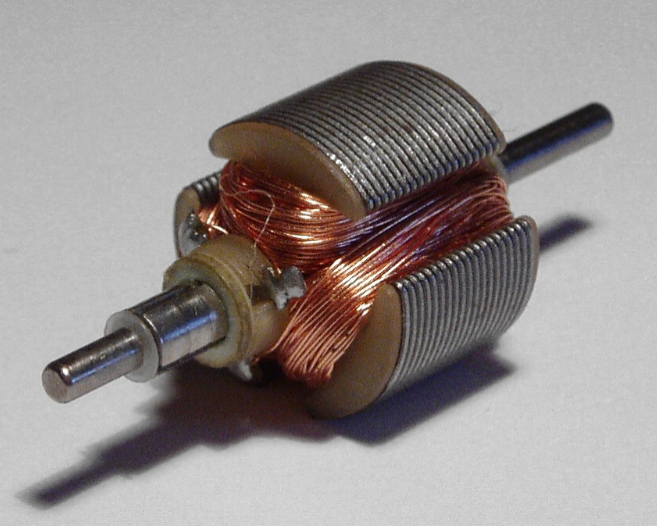

The rotating part of the motor, that includes the armature and

commutator is called the rotor. The armature is the rotating coil. The

commutator is a split ring that rotates with the armature. The

stationary part, including the field magnets, brushes and housing is

called the stator.

|

The rotor from a simple permanent magnet DC motor. You can see the split in the commutator on the left side of the shaft. |

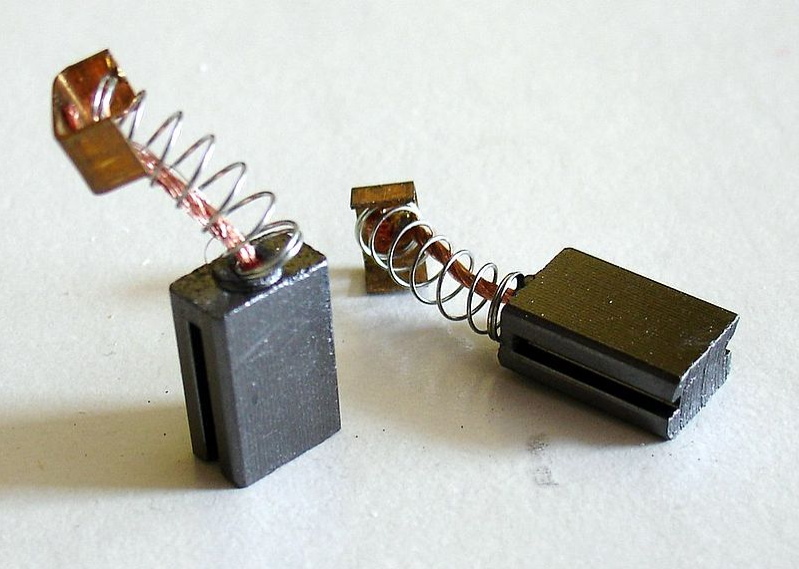

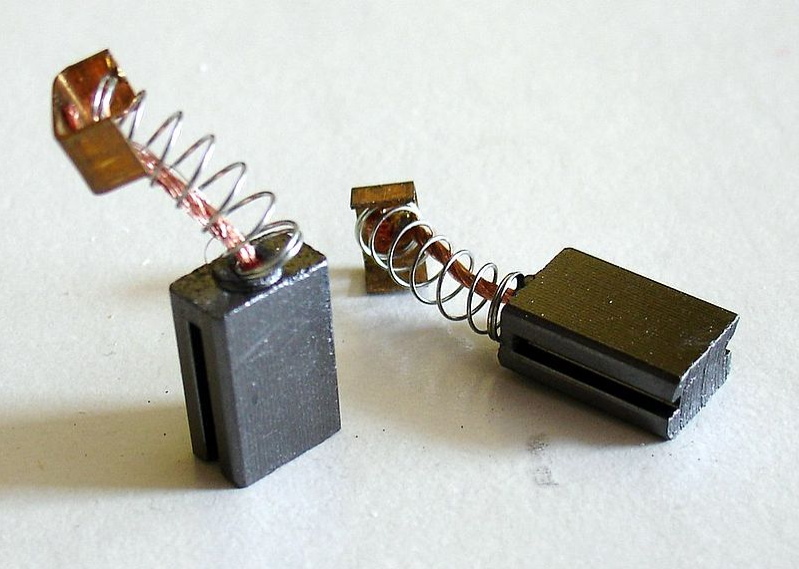

The brushes, often made of carbon, contact the commutator to provide power to the armature.

The field magnets are the permanent magnets or electromagnets that provide a magnetic field for the armature to interact with.

As the commutator rotates the brushes stay in contact with it

continuing to supply power. The commutator also acts as a switch. With

each half-turn of the armature, the commutator changes which direction

the current flows through the coil. During one half-turn the armature

is magnetized in one direction and during the other half-turn it is

magnetized in the other. When the armature lines up with the field

magnets the commutator reverses the polarity of the armature so that

the magnetic fields push then pull the armature another half turn to

line them up again. This repeats over and over as the motor turns.

|

|

| The current through the armature causes the magnetic field to be

oriented as shown. The north pole of the armature is attracted to the

south pole of the left magnet. Likewise, the south pole of the armature

is attracted to the north pole or the right magnet.

|

|

| |

|

|

|

| This magnetic interaction causes the armature to rotate counter

clockwise. The poles of the armature try to line up with the poles of

the field magnets. |

|

| |

|

|

|

| Momentum carries the armature past the magnets as the commutator swaps the battery connection. |

|

| |

|

|

|

| The commutator has switched the poles of the armature. Now the north

pole of the armature is repelled from the north pole of the right

magnet and vice versa. The armature continues to rotate. |

|

| |

|

|

|

| Now the armature has made ½ turn. The former north pole is now the

south pole and vice versa. The next half cycle begins like the first. |

|

| |

|

How do you know which end of the armature will be north and which will

be south. Make a fist with your right hand with the thumb pointing out.

Your fingers curl in the direction of conventional current and you

thumb points to the north pole. This is called the right hand rule. For

electron flow use your left hand.

Generators

A DC generator is exactly the same as a DC motor. If you spin the

armature of a DC motor it will produce DC voltage (and current if there

is a circuit between the terminals). You can demonstrate this by

putting a voltmeter or current meter across a motor and spinning the

armature. You may even get enough current to run a small light bulb or

LED. Before nuclear submarines, many diesel submarines used motors to

run the propellers from batteries when submerged. When surfaced, diesel

engines turned the propellers. Since the electric motors were on the

propeller shafts they were also turned by the engines. Therefore, while

surfaced the motors were used as generators to charge the batteries.

1

Often electric vehicles use the traction motors (the motors that turn

the wheels of the vehicle) as generators. While braking they put some

charge back into the battery.

If you short the terminals on a motor the motor will self-brake. This

is because turning the armature generates current. This current creates

a magnetic field that tries to turn the motor in the opposite direction

to which it is rotating. You can demonstrate this by spinning the

armature of a small electric motor. It should spin freely. Next use a

clip lead to short the terminals together and spin the armature again.

You will see that the armature quickly stops. Electric trains, from

light rail to heavy diesel-electric locomotives often use this effect

to help slow or stop the vehicle. This called dynamic braking.

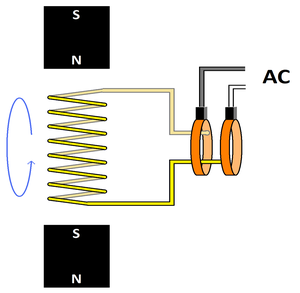

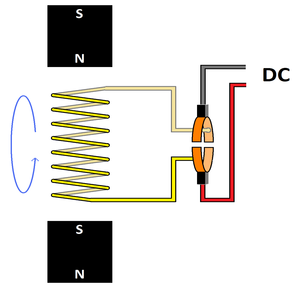

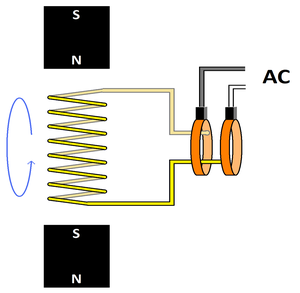

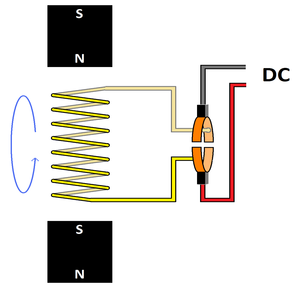

A slight change in design creates an AC generator or alternator.

Instead of a commutator (a single split slip ring) an alternator has

two complete slip rings with a brush on each. A commutator will cause

the generator to produce DC. It acts as a switch to cause the current

to flow in only one direction.

|

|

A generator with slip rings instead of a commutator produces alternating current and is called an alternator. |

|

|

|

|

A commutator causes the generator to produce direct current (this is identical to a DC motor). |

Although this design with slip rings will produce AC, this is not how

working alternators are designed. In typical alternators the

armature is fed DC through the slip rings making the armature an

electromagnet. The armature rotates inside the stator which is

lined with coils. Alternating current is produced in the stator coils

as the armature's magnetic field spins past them. Alternators will be

covered in more detail in the volume on AC circuits.

Here is an interactive

simulation

of an alternator and generator:

Small DC motors are usually made with permanent magnets. Before the

development of rare earth magnets permanent magnets were not powerful

enough for large motors. Large motors are usually made with

electromagnets for the field magnets. The permanent magnets are

replaced with coils of wire called field coils as shown below. There

are two ways to make electromagnet motors: series wound and shunt wound.

|

| Series wound electromagnet DC motor |

|

|

Shunt wound electromagnet DC moror |

|

|

Series wound motors have the field coils connected in series with the

armature. Shunt wound motors have the field coils connected in parallel

with the armature (i.e. a shunt or bypass). A shunt wound motor

typically runs at a fairly constant speed regardless of the load

2 when

operated within its design parameters. This is because the strength of

the magnetic field from the field winding is relatively unaffected by

the current through the armature winding.

As mentioned above, a DC motor is also a generator. When a motor is

spinning it produces current that opposes the current that is driving

the motor. This is called back EMF just as is the the current produced

by self induction. When a motor is slowed by a heavy load it produces

less back EMF. Therefore more current flows into the motor and it

produces more torque. This is a convenient negative feedback system.

When a motor is lightly loaded it needs and has less torque but when

heavily loaded it needs and has more torque. This effect is much more

pronounced in a series wound motor. With the field coils in series with

the armature you get more current in the field coils as well as the

armature when the motor is slowed by a heavy load. A series wound motor

should never be operated with no load. It will turn at such a high

speed that centrifugal force could damage it. For example, a series

motor would not be used to drive a belt because if the belt slips the

motor could spin fast enough to damage itself.

Some small DC motors are made with a two coil armature similar to the

diagrams above. However, they are usually made with three or more coils

in the armature.

|

| A rotor from a permanent magnet DC motor with a three-coil armature.

Like most motors, the armature has a core made of laminated soft iron.

|

|

|

|

|

|

Wiring of a three coil armature and commutator.

|

|

|

Each coil has its own contact on the commutator so most commutators

have more than the two splits shown in the diagrams. Having multiple

coils in the armature increases efficiency. Only the coils near the

field magnets are energized leaving the others dormant while they are

far from the magnets.

1

|

Many submarines were also

designed more like a diesel-electric locomotive. The diesel engines ran

generators that both charged the batteries and ran the motors on the

propeller shafts. On these designs there was no mechanical connection

between the diesel engines and the propellers.

|

| 2 |

In this case the load is

how much whatever the motor is turning resists that turning force. In

other words, how hard the motor is working.

|